Traceability (1) - Automated Stock Barcode Solution

The first step of traceability is to create the barcode coding of the inventory code to be defined in the existing ERP system.

In this context, defining separate barcodes for each stock defined on NETSIS, and the controllability of the unit of measure in this coding will make the process even more complicated.

All these operations will be defined automatically with the Triger definition given below to the TBLSTSABIT table where inventory definitions are performed on Netsis and possible errors will be prevented.

A coding standard has been established on the trigger based on "KG" and "PCS" sized units.

================================================== ================================ CREATE TRIGGER [dbo]. [BARCODOLUSTUR] ON

[dbo]. [TBLSTSABIT] FOR INSERT, UPDATE

AS BEGIN

DECLARE @STOKKODU TDBSTOKKOD

DECLARE @ OLCUBR1 VARCHAR (2)

DECLARE @BARKODNO VARCHAR (35)

DECLARE @TARIH SMALLDATETIME

SELECT @ TARIH = CAST (FLOOR (CAST (GETDATE () AS FLOAT)) AS SMALLDATETIME)

DECLARE STOCK CODE_CRS cursor for

SELECT STOCK_ CODE, OLCU_BR1

FROM INSERTED with (NOLOCK)

OPEN STOCK CODE_CRS

FETCH STOKKODU_CRS into

@ STOCK CODE, @ OLCUBR1

WHILE (@@ FETCH_STATUS <> -1) BEGIN

IF ISNULL ((SELECT COUNT (*) FROM TBLSTOKBAR WHERE STOCK_ CODE = @ STOCK CODE), 0) <> 0

GOTO DONE

IF UPPER (ISNULL (@ OLCUBR1, '')) = 'KG' or UPPER (ISNULL (@ OLCUBR1, '')) = 'MT' or UPPER (ISNULL (@ OLCUBR1, '')) = 'LT' or UPPER (ISNULL (@ OLCUBR1, '')) = 'M2'

GOTO FIRST ARTICLE_28

IF UPPER (ISNULL (@ OLCUBR1, '')) = 'KT' OR UPPER (ISNULL (@ OLCUBR1, '')) = 'TK' OR UPPER (ISNULL (@ OLCUBR1, '')) = 'VR' OR UPPER (ISNULL (@ OLCUBR1, '')) = 'TB' OR UPPER (ISNULL (@ OLCUBR1, '')) = 'PK' OR UPPER (ISNULL (@ OLCUBR1, '')) = 'AD' OR UPPER (ISNULL (@ OLCUBR1, '')) = 'PL'

GOTO FIRST ARTICLE_29

-------------------------------------------------- -------------------------------------------------- -----------

GOTO DONE

-------------------------------------------------- -------------------------------------------------- -----------

FIRST ARTICLE_28:

SELECT @BARKODNO = '28' + RIGHT ('00000' + (SELECT CAST (CAST (MAX (RIGHT (BARKOD, 5)) AS INT) +1 AS VARCHAR) FROM TBLSTOKBAR WHERE LEN (BARKOD) = 7 AND BARKOD LIKE ' 28% '), 5)

INSERT INTO TBLSTOKBAR

(STOK_KODU, BARCODE, BARTIP, BARTARIH, I_YEDEK1)

VALUES (@ STOKKODU, @ BARKODNO, 'T', @ DATE, '1')

GOTO DONE

-------------------------------------------------- -------------------------------------------------- -----------

FIRST ARTICLE_29:

SELECT @BARKODNO = '29' + RIGHT ('00000' + (SELECT CAST (CAST (MAX (RIGHT (BARKOD, 5)) AS INT) +1 AS VARCHAR) FROM TBLSTOKBAR WHERE LEN (BARKOD) = 7 AND BARKOD LIKE ' 29% '), 5)

INSERT INTO TBLSTOKBAR

(STOK_KODU, BARCODE, BARTIP, BARTARIH, I_YEDEK1)

VALUES (@ STOKKODU, @ BARKODNO, 'T', @ DATE, '1')

GOTO DONE

-------------------------------------------------- -------------------------------------------------- -----------

DONE:

fetch STOKKODU_CRS into

@ STOCK CODE, @ OLCUBR1

end

close STOK CODE_CRS

deallocate STOCK CODE_CRS

end

Traceability (2) - Serial Lot / Lot Number

Within the scope of traceability, our second most important criterion after BARCODE coding is that each production can be controlled on separate cooling numbers.

Serial numbers are defined by the system separately for each product or raw material and are unique. The serial numbers are defined separately based on the FEFO or FIFO criteria through the serial tracking.

For example, each mobile phone has its own IMEI number. This numbering process is uniquely identified by the system for that stock.

While lot numbers are applied to product groups, serial numbers are defined separately for a specific product.

Traceability (3) - Netsis Serial Lot / Lot Number

Within the scope of traceability, our second most important criterion after BARCODE coding is that each production can be controlled on separate cooling numbers.

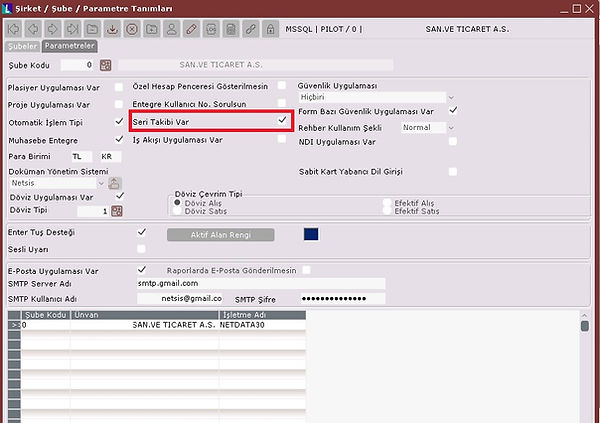

In Netsis Enterprise / Standard / Integrated programs, firstly, company branch parameters are opened under the utility module for serial / lot tracking. From here, "Serial Follow-Up" parameter is marked and the parameter is saved with the F5 record adding key or (+) record adding key.

Important Note: Before activating the Series Application, it is beneficial to activate the serial inventory count operation or at the beginning of the year. This is because there will be a difference between the series stock balance and inventory balance reports, due to this reason, in the balance reports.

In order to prevent this situation, my suggestion is to activate the serial stock count operation in the middle of the year, and then activate the stock control operation with series at the beginning of the year.

When the serial tracking parameter becomes active, the "serial tracking" tab will appear on the inventory card records. In this tab content, it is necessary to click on the boxes in the correspondence of all the fields indicated in the image below.

According to these parameters marked on the basis of the inventory card, serial entry will be mandatory for system stock movements (purchase-sales, transfer between warehouses, warehouse receipts, etc.). I recommend that the "Check balance" parameter should be marked on stocks to be followed up in series or lots. Thus, exit from a non-serial / lot number is prevented. If the “Ask for serial amount” parameter is checked, it will be understood that serial tracking will be performed on the related card, otherwise lot number will be followed on this card.

Traceability (4) - Serial Parameter Configuration

We access Serial Parameter records via SERIAL PARAMETERS on LOGISTICS-SALES \ STOCK \ RECORD \ SERIES TRACKING.

The most important details in terms of traceability are determined under this parameter.

Therefore, we will examine the specified parameters, which are important. From now on, I must say that the most important parameter is SERIAL NO-3 and SERIAL NO - 4 because embedding party \ lot \ serial information received from the Supplier during raw material acceptance in this field will provide maximum return on traceability inquiries.

Single Series Based on Stock: It is the parameter used to make the series unique on stock basis.

Optional Fields to be Used in Series Entry: If the most important will be SERIES NO-3 and SERIES NO - 4 and FEFO, of course EXPIRATION DATE

Require Serial Entry in Serial Tracking Screen: It is the parameter that obliges serial entry by preventing the screen from closing when the entered serial amount is "0" in the "Serial Tracking" screen.

Automatically Calculate Serial Code for Entries: It is the parameter that allows the program to automatically calculate the serial number for the inventory entries to be made manually from the Inventory Movement Records (manually) and automatically from the Invoice / Production Module, according to the responses to be given to other parameters. When the parameter is selected, Inventory Transaction Records, at the entries made from the Production and Invoice Modules, at least 1 serial (depending on the inventory card serial parameters) is automatically calculated and displayed in the opened serial window.

When the Inventory → Registration → Inventory Card Records → Series Follow-up → “Ask Series Up to Quantity” parameter is checked, the serial is automatically calculated as the amount entered in the inventory entries. If it is not checked, 1 batch is calculated for the entered amount and the amount of this batch is corrected when requested, and it is allowed to enter the batch manually for the remaining quantities.

When the "Automatically Calculate Serial Code for Entries" parameter is not checked, the automatic calculation that is queried separately in the inventory cards is not performed. If automatic calculation will be made in some cards and manual (manual) serial entry for some cards, it is recommended to mark this parameter and make the distinction on the basis of cards.

Include Year Information in Serial Number: It is the parameter that becomes active when one of the parameters "Let Serial Code be Calculated Automatically for Inputs / Outputs" is marked. When the parameter is marked, the year information is included in the serial number to be calculated automatically.

For example;

When the batch is calculated for a stock with the code "CEPTEL", the resulting batch is like "CEPTEL20011".

Serial Number Length: It is the field that becomes active when any of the parameters "Calculate Serial Code Automatically for Inputs / Outputs" is checked. For serial numbers to be calculated automatically, the maximum length to be entered is determined. Here, serial number is created for the specified length.